Nominated innovations

1000 innovative clean energy solutions and > 150 framework enablers with the potential to deliver more than twelve gigatonnes of avoided emissions by 2030

These assessments are based on a basic avoided emission assessment. The overall concept of avoided emissions is that a solution (product or service) enables the same function to be performed with significantly less GHG emissions. The method of measuring avoided emissions, is to compare a baseline scenario without the enabling solution, with a scenario using the enabling solution; whereby the baseline represents the ‘business as usual’ (BAU) scenario.

These assessments are based on the framework document: The Avoided Emissions Framework (AEF) from September 2020

Data on greenhouse gas emissions in the food industry

The food industry is responsible for 20-25% of the total GHG emission. CarbonCloud AB has developed services which is intended help food producers and restaurants to reduce their mark on the environment by providing up-to-date emissions data for the individual food producers’ products. The services are created both to help chefs and other executives to understand their products impact, but also to enable their customers to make environmentally friendly decisions. All of this is done using an app which performs all the calculations for the food providers. It also includes a calendar and automatic data updates.

Sweden

≈100

CarbonCloud AB

Data on greenhouse gas emissions in the food industry

The food industry is responsible for 20-25% of the total GHG emission. CarbonCloud AB has developed services which is intended help food producers and restaurants to reduce their mark on the environment by providing up-to-date emissions data for the individual food producers’ products. The services are created both to help chefs and other executives to understand their products impact, but also to enable their customers to make environmentally friendly decisions. All of this is done using an app which performs all the calculations for the food providers. It also includes a calendar and automatic data updates.

≈100Mt CO2e/year

Decentralized biomethane mobility solutions

Atmove offers products and services necessary for decentralized biomethane mobility. The Atmove circular economy system offers an integration of biogas infrastructure to use organic waste from the agriculture, biomethane upgrading, BioGNG filling stations, vehicles and services within a one-stop-shop. According to Atmove, their solution compared to fossil alternatives cuts fuel costs by 50% and CO₂ emissions by 90% with a standardized product range that covers 80 % of the market needs.

Brazil

≈100

Atmove

Decentralized biomethane mobility solutions

Atmove offers products and services necessary for decentralized biomethane mobility. The Atmove circular economy system offers an integration of biogas infrastructure to use organic waste from the agriculture, biomethane upgrading, BioGNG filling stations, vehicles and services within a one-stop-shop. According to Atmove, their solution compared to fossil alternatives cuts fuel costs by 50% and CO₂ emissions by 90% with a standardized product range that covers 80 % of the market needs.

≈100Mt CO2e/year

Energy storage in graphene-based super capacitators

Graphene can be used to make aluminium composite materials. One problem with using graphene is that it easily agglomerates and cannot be used that extensively for that reason. The Aros Graphene solves this problem and makes it possible to use graphene to make aluminium composite materials. Graphene is a highly conductive and lightweight material that can be used to make aluminium composite materials. According to Graphmatech AB, using graphene in aluminium composite can reduce about 50-70 % of aluminium in products. This means that about 50-70 % less energy for aluminium production is needed.

Sweden

≈100

GraphMaTech AB

Energy storage in graphene-based super capacitators

Graphene can be used to make aluminium composite materials. One problem with using graphene is that it easily agglomerates and cannot be used that extensively for that reason. The Aros Graphene solves this problem and makes it possible to use graphene to make aluminium composite materials. Graphene is a highly conductive and lightweight material that can be used to make aluminium composite materials. According to Graphmatech AB, using graphene in aluminium composite can reduce about 50-70 % of aluminium in products. This means that about 50-70 % less energy for aluminium production is needed.

≈100Mt CO2e/year

Cost-competitive solar heat though optimised lenses

Heliac’s solar collectors produce utility-scale heat at unsubsidized costs they claim is below that of fossil fuels anywhere in the world. By using inexpensive lenses that work like magnifying glasses, it can generate temperatures up to 400 °C. Heliac targets process heat markets responsible for 15% of the global demand. These markets include desalination, district heating and cooling, and heat for numerous other standard industrial processes. Heliac believes their solution is scalable enough to meet any potential demand today.

Denmark

≈100

Heliac

Cost-competitive solar heat though optimised lenses

Heliac’s solar collectors produce utility-scale heat at unsubsidized costs they claim is below that of fossil fuels anywhere in the world. By using inexpensive lenses that work like magnifying glasses, it can generate temperatures up to 400 °C. Heliac targets process heat markets responsible for 15% of the global demand. These markets include desalination, district heating and cooling, and heat for numerous other standard industrial processes. Heliac believes their solution is scalable enough to meet any potential demand today.

≈100Mt CO2e/year

Electric three-wheeler city taxi

Bzzt Taxi Pods provides an app-based taxi service in urban areas through the use of small electrically powered 3-wheel taxis at the price point of public transport and with zero local emissions. All the taxi pods in the fleet are Light Electrical Vehicles and the fleet operation is optimized with an inhouse software. Onwards, the fleet could also serve as a flexible and low emission alternative for last mile urban deliveries.

Sweden

≈100

Bzzt

Electric three-wheeler city taxi

Bzzt Taxi Pods provides an app-based taxi service in urban areas through the use of small electrically powered 3-wheel taxis at the price point of public transport and with zero local emissions. All the taxi pods in the fleet are Light Electrical Vehicles and the fleet operation is optimized with an inhouse software. Onwards, the fleet could also serve as a flexible and low emission alternative for last mile urban deliveries.

≈100Mt CO2e/year

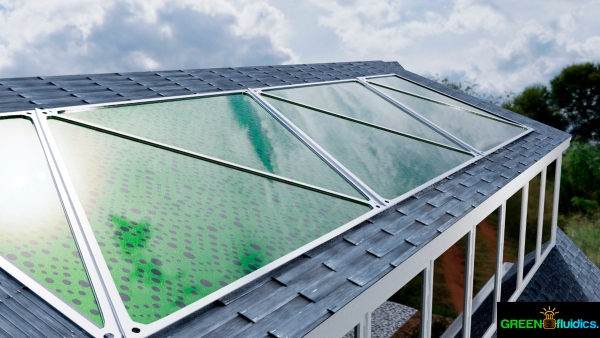

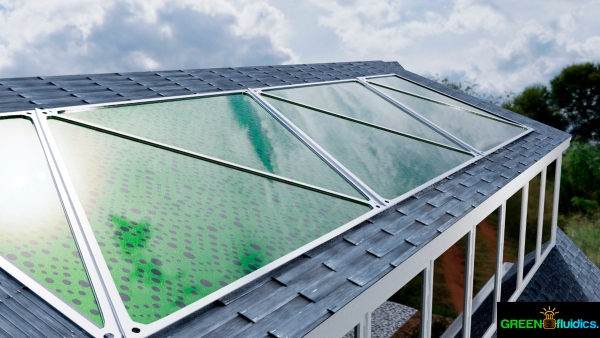

Electricity-generating CO₂-absorbing bio-panel

GREENFLUIDICS produces a solar bio-panel that integrates the capture of CO₂, production of oxygen, metabolized heat and capture of solar radiation efficiently via nano-fluids. Contrary to the usual solid state solar cells the bio-panel is a full spectrum solar collector including infrared radiation, including an automated monitoring of energy efficiency and metabolic variables with sensors integrated with IoT and data analytics, allowing a conversion of light and heat into energy at the same time.

Mexico

≈100

Greenfluidics

Electricity-generating CO₂-absorbing bio-panel

GREENFLUIDICS produces a solar bio-panel that integrates the capture of CO₂, production of oxygen, metabolized heat and capture of solar radiation efficiently via nano-fluids. Contrary to the usual solid state solar cells the bio-panel is a full spectrum solar collector including infrared radiation, including an automated monitoring of energy efficiency and metabolic variables with sensors integrated with IoT and data analytics, allowing a conversion of light and heat into energy at the same time.

≈100Mt CO2e/year

Harvesting heat from cities

Heat Harvest addresses the need for cooling in urban hot spots. The standard solution is to install air conditioning units and blow the hot air outside. This solution is not is suitable in densely populated city areas. Thus, other technical solutions are sought. Heat Harvest intends to cool pavements and building walls which are directly exposed to sunlight with water cooling lines which are directly enclosed in concrete, asphalt etc. which therefore have extremely low maintenance needs.

Austria

≈100

Climathon Project Heat Harvest

Harvesting heat from cities

Heat Harvest addresses the need for cooling in urban hot spots. The standard solution is to install air conditioning units and blow the hot air outside. This solution is not is suitable in densely populated city areas. Thus, other technical solutions are sought. Heat Harvest intends to cool pavements and building walls which are directly exposed to sunlight with water cooling lines which are directly enclosed in concrete, asphalt etc. which therefore have extremely low maintenance needs.

≈100Mt CO2e/year

Optimization of heating and cooling solutions

The innovation is an analytic tool that can be applied to Heating, Ventilation, Airconditioning and Refrigeration (HVACR) systems, to detect deviations and in the end save energy. The analytics can detect performance losses in refrigeration systems and pinpoint where the deviation occurs. Either monitoring sensors are installed in combination with the analysis tool, or there are available sensors that the tool can connect to. Optimal operation and predictive maintenance can save energy and in turn reduce the need for energy production.

Sweden

≈100

Climacheck Sweden AB

Optimization of heating and cooling solutions

The innovation is an analytic tool that can be applied to Heating, Ventilation, Airconditioning and Refrigeration (HVACR) systems, to detect deviations and in the end save energy. The analytics can detect performance losses in refrigeration systems and pinpoint where the deviation occurs. Either monitoring sensors are installed in combination with the analysis tool, or there are available sensors that the tool can connect to. Optimal operation and predictive maintenance can save energy and in turn reduce the need for energy production.

≈100Mt CO2e/year

Electricity from waste heat

A substantial part of the energy used in the world is wasted as heat. Climeon AB has developed a solution to convert waste heat with temperatures between 70 and 120 °C into electricity through a vacuum process. One of the company’s key sectors is the marine sector where the Climeon Ocean™ solution converts waste heat from ship engines, creating up to several GWh of “free” electricity each year. The company claims that for some ships, that translates into a savings of more than 1,000 metric tons of fuel or 3,000 metric tons of CO₂ per year. An even larger sector is steel where Swedish steel producer SSAB running Climeon Ocean™ at their production site in Borlänge.

Sweden

≈10

Climeon AB

Electricity from waste heat

A substantial part of the energy used in the world is wasted as heat. Climeon AB has developed a solution to convert waste heat with temperatures between 70 and 120 °C into electricity through a vacuum process. One of the company’s key sectors is the marine sector where the Climeon Ocean™ solution converts waste heat from ship engines, creating up to several GWh of “free” electricity each year. The company claims that for some ships, that translates into a savings of more than 1,000 metric tons of fuel or 3,000 metric tons of CO₂ per year. An even larger sector is steel where Swedish steel producer SSAB running Climeon Ocean™ at their production site in Borlänge.

≈10Mt CO2e/year

Carbonlites – innovative biogas production

Globally, approximately 11.2 billion tons of waste is generated every year and is amongst the biggest threats affecting our ecosystem. Solid waste dumped at landfill sites produce large amounts of methane, which accounts for 12% of total global methane emissions. Carbon Masters has developed a method for managing the organic waste by collecting and converting the waste into useful fuel. Waste is collected and then treated anaerobically to produce methane gas and organic slurry. The gas is purified, compressed and used as a substitute to LPG for cooking and as fuel in vehicles, while the slurry is treated to produce organic manure used as a replacement to chemical fertilizers.

India

≈10

Carbon Masters India Pvt. Ltd.

Carbonlites – innovative biogas production

Globally, approximately 11.2 billion tons of waste is generated every year and is amongst the biggest threats affecting our ecosystem. Solid waste dumped at landfill sites produce large amounts of methane, which accounts for 12% of total global methane emissions. Carbon Masters has developed a method for managing the organic waste by collecting and converting the waste into useful fuel. Waste is collected and then treated anaerobically to produce methane gas and organic slurry. The gas is purified, compressed and used as a substitute to LPG for cooking and as fuel in vehicles, while the slurry is treated to produce organic manure used as a replacement to chemical fertilizers.

≈10Mt CO2e/year