Nominated innovations

1000 innovative clean energy solutions and > 150 framework enablers with the potential to deliver more than twelve gigatonnes of avoided emissions by 2030

These assessments are based on a basic avoided emission assessment. The overall concept of avoided emissions is that a solution (product or service) enables the same function to be performed with significantly less GHG emissions. The method of measuring avoided emissions, is to compare a baseline scenario without the enabling solution, with a scenario using the enabling solution; whereby the baseline represents the ‘business as usual’ (BAU) scenario.

These assessments are based on the framework document: The Avoided Emissions Framework (AEF) from September 2020

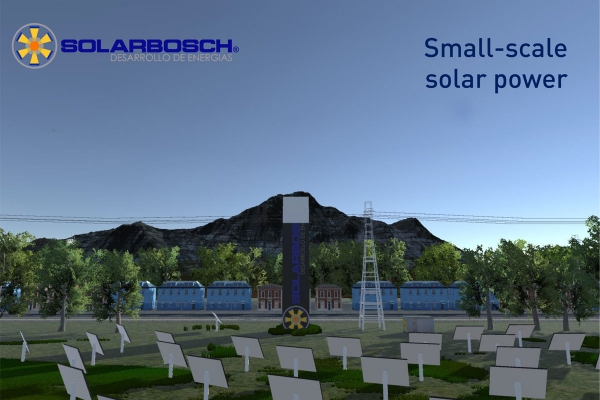

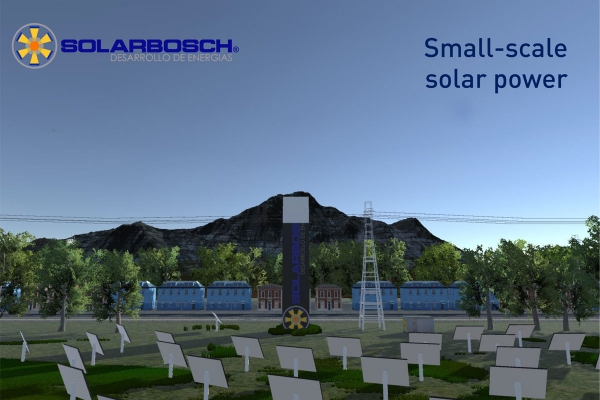

Design of small-scale concentrated solar power plants

In a project called 'Solarbosch', Enerbosh is developing small-scale concentrated solar power tower (CSP-T) plants, with ranges from 0.5 to 3 MWe for power generation or 1 to 10 MWh for heat processes on a 24/7 basis. Current CSP-T plants use molten salts as heat transfer fluid (HTF) and storage medium, reaching temperatures up to 560 °C. This is only profitable at very large scales due to the high investment required. In this project the CSP-T plant uses air as HTF, which can easily exceed 1000 °C. The heat storage medium is copper slag, a Chilean mining industry by-product (low cost), with ideal heat storage properties up to 1,000 °C.

Chile

≈10

Enerbosch

Design of small-scale concentrated solar power plants

In a project called 'Solarbosch', Enerbosh is developing small-scale concentrated solar power tower (CSP-T) plants, with ranges from 0.5 to 3 MWe for power generation or 1 to 10 MWh for heat processes on a 24/7 basis. Current CSP-T plants use molten salts as heat transfer fluid (HTF) and storage medium, reaching temperatures up to 560 °C. This is only profitable at very large scales due to the high investment required. In this project the CSP-T plant uses air as HTF, which can easily exceed 1000 °C. The heat storage medium is copper slag, a Chilean mining industry by-product (low cost), with ideal heat storage properties up to 1,000 °C.

≈10Mt CO2e/year

High capacity drone spreading system

Nordluft Automation offers solutions of forestry and agriculture spreading systems using drones. The solutions offered by the company are focused on two areas: First, forest fertilization, where a group of drones combined with a platform can be used to increase the growth rate of forests while also increasing the amount of CO2 absorbed per area unit. The second main application is ash recycling, where ash created as a by-product in different applications is spread to provide forests with additional nutrients. For both applications, Nordluft has developed their own specialized drone, the NordKopter.

Sweden

Nordluft automation AB

High capacity drone spreading system

Nordluft Automation offers solutions of forestry and agriculture spreading systems using drones. The solutions offered by the company are focused on two areas: First, forest fertilization, where a group of drones combined with a platform can be used to increase the growth rate of forests while also increasing the amount of CO2 absorbed per area unit. The second main application is ash recycling, where ash created as a by-product in different applications is spread to provide forests with additional nutrients. For both applications, Nordluft has developed their own specialized drone, the NordKopter.

Currently unavailable

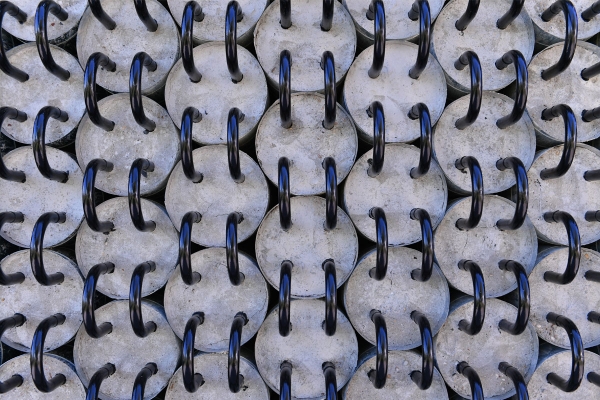

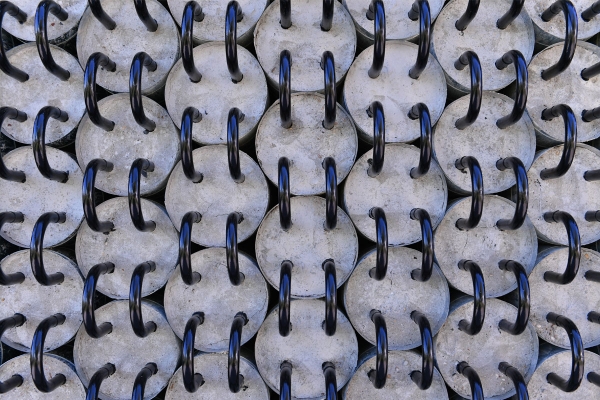

Grid-scale thermal storage using solid-state material

EnergyNest developed a thermal battery for thermal power plants and energy-intensive industries. The company recently installed and commissioned a pilot system with a combined capacity of 1 MWth. The company says that the system was operated over more than 6,000 hours with an energy cycling profile resembling operation in a power plant. In 2018, a first free-standing commercial module was manufactured and displayed at the company’s assembly site in Rotterdam. Since the technology’s two main materials – concrete and steel – are available and recyclable, it can be deployed in any geographical location, and up to 80% of the storage materials can be sourced locally.

Norway

≈10

EnergyNest AS

Grid-scale thermal storage using solid-state material

EnergyNest developed a thermal battery for thermal power plants and energy-intensive industries. The company recently installed and commissioned a pilot system with a combined capacity of 1 MWth. The company says that the system was operated over more than 6,000 hours with an energy cycling profile resembling operation in a power plant. In 2018, a first free-standing commercial module was manufactured and displayed at the company’s assembly site in Rotterdam. Since the technology’s two main materials – concrete and steel – are available and recyclable, it can be deployed in any geographical location, and up to 80% of the storage materials can be sourced locally.

≈10Mt CO2e/year

Energy efficient ceiling fan

Atomberg Technologies aims to use their innovative Gorilla Ceiling Fan to reduce power consumption of cooling compared to conventional fans. The company claims that, whereas other fans consume around 75 Watts at full speed, Gorilla fans consume only 28 Watts; achieved using a brushless DC motor design and a driving algorithm called “atomsense”, which precisely senses various motor parameters in real time and controls the motor in a closed loop, avoiding power losses.

India

≈10

Atomberg Technologies Private Limited

Energy efficient ceiling fan

Atomberg Technologies aims to use their innovative Gorilla Ceiling Fan to reduce power consumption of cooling compared to conventional fans. The company claims that, whereas other fans consume around 75 Watts at full speed, Gorilla fans consume only 28 Watts; achieved using a brushless DC motor design and a driving algorithm called “atomsense”, which precisely senses various motor parameters in real time and controls the motor in a closed loop, avoiding power losses.

≈10Mt CO2e/year

Pulp-based studs as building material

Wood Tube Sweden produces pulp-based studs for inside walls and furniture. The studs are similar to traditional wooden planks, but utilize a hollow design. It has a lower weight and price compared to alternatives and, due to the hollowness, its greather surface can be treated for improvement. The attributes can lower costs of construction while reducing environmental impact from heavy materials and newly-sourced timber.

Sweden

≈10

Wood Tube Sweden AB

Pulp-based studs as building material

Wood Tube Sweden produces pulp-based studs for inside walls and furniture. The studs are similar to traditional wooden planks, but utilize a hollow design. It has a lower weight and price compared to alternatives and, due to the hollowness, its greather surface can be treated for improvement. The attributes can lower costs of construction while reducing environmental impact from heavy materials and newly-sourced timber.

≈10Mt CO2e/year

Solid-state refrigerator

India's National Physical Laboratory has developed a portable, solid state cooling technology that does not require the compressor or refrigerant found in conventional refrigerators. It can therefore be operated at a low-power supply of only 75 Watts DC, e.g. directly from solar photovoltaic cells and batteries. The purpose of the innovation is two-fold: first, as a low-cost comfort and food storage solution to rural populations, and second, to compliment India’s immunization program for rural populations of children by storing vaccines at low temperatures. With a long lifespan and needing little maintenance, the solid state cooler maintains 5 °C at an ambient temperature of 40 °C but can cool to -2 °C if required.

India

≈1

National Physical Laboratory New Delhi

Solid-state refrigerator

India's National Physical Laboratory has developed a portable, solid state cooling technology that does not require the compressor or refrigerant found in conventional refrigerators. It can therefore be operated at a low-power supply of only 75 Watts DC, e.g. directly from solar photovoltaic cells and batteries. The purpose of the innovation is two-fold: first, as a low-cost comfort and food storage solution to rural populations, and second, to compliment India’s immunization program for rural populations of children by storing vaccines at low temperatures. With a long lifespan and needing little maintenance, the solid state cooler maintains 5 °C at an ambient temperature of 40 °C but can cool to -2 °C if required.

≈1Mt CO2e/year

Solar powered small-scale agricultural machines

ALTO precision’s aim is to develop a range of solar-powered small-scale decentralised machinery for remote small holding agri-processing needs in India. Their current developments include a range of small-scale rice processing machines. The solar rice huller is a 360 W machine that can produce 100 kg/hour with a hulling efficiency of 98% in the first pass, which ALTO precision claims is the most efficient small-scale rice processing machine in the world, almost 50% more efficient than any other machine, at a low price. The machines are solar powered, high capacity and very efficient, giving farmers access to a sustainable energy source and providing food security and the opportunity to create an additional income.

India

≈1

ALTO Precision

Solar powered small-scale agricultural machines

ALTO precision’s aim is to develop a range of solar-powered small-scale decentralised machinery for remote small holding agri-processing needs in India. Their current developments include a range of small-scale rice processing machines. The solar rice huller is a 360 W machine that can produce 100 kg/hour with a hulling efficiency of 98% in the first pass, which ALTO precision claims is the most efficient small-scale rice processing machine in the world, almost 50% more efficient than any other machine, at a low price. The machines are solar powered, high capacity and very efficient, giving farmers access to a sustainable energy source and providing food security and the opportunity to create an additional income.

≈1Mt CO2e/year

Organic Rankine Cycle turbine

Low-temperature heat can be captured and converted into electricity through the Organic Rankine Cycle (ORC) system. Againity takes advantage of low-temperature heat down to 90 degrees and can perform with systems in the range of 50-2500 kW energy production. The modularity of the Againity solution means they can be combined and scaled. Automation steers the system but can also be remotely controlled. The intended market is for heat sources from water boilers, treatment plants, or industrial processes.

Sweden

≈1

Againity AB

Organic Rankine Cycle turbine

Low-temperature heat can be captured and converted into electricity through the Organic Rankine Cycle (ORC) system. Againity takes advantage of low-temperature heat down to 90 degrees and can perform with systems in the range of 50-2500 kW energy production. The modularity of the Againity solution means they can be combined and scaled. Automation steers the system but can also be remotely controlled. The intended market is for heat sources from water boilers, treatment plants, or industrial processes.

≈1Mt CO2e/year

Automatically created transport solutions for events

Existing transport infrastructure often reaches its capacity limits at events, for example, which is why alternative solutions are required at short notice. Triply offers a possibility to estimate the arrival routes of the visitors in advance and to provide alternative mobility solutions for the transport. Finding stops and routing are optimized by an underlying triply algorithm, which saves money and valuable time. Triply offers a possibility to clearly display the coverage of public transport systems and to visualize the effects of changes on the accessibility. The interactive map can be used as a basis for planning or for external communication.

Austria

≈1

Climathon Project Triply

Automatically created transport solutions for events

Existing transport infrastructure often reaches its capacity limits at events, for example, which is why alternative solutions are required at short notice. Triply offers a possibility to estimate the arrival routes of the visitors in advance and to provide alternative mobility solutions for the transport. Finding stops and routing are optimized by an underlying triply algorithm, which saves money and valuable time. Triply offers a possibility to clearly display the coverage of public transport systems and to visualize the effects of changes on the accessibility. The interactive map can be used as a basis for planning or for external communication.

≈1Mt CO2e/year

Coolar refrigerator using solar heated warm water

Coolar has produced an electricity-independent medical refrigerator. The Coolar system uses warm water that is heated through solar energy and stored in a water tank. It does not use any moving parts, hazardous cooling fluids or lubricants. Thus, the Coolar system is a cheap, durable and sustainable solution for storage of vaccines, medicines and food in regions with unreliable or expensive electricity. The Coolar system runs independently from electricity by using solar heat, which makes it almost carbon neutral. Such a refrigerator can enable doctors and health professionals to preserve lifesaving medicine and vaccines in a reliable and eco-friendly way.

Germany

≈1

Coolar

Coolar refrigerator using solar heated warm water

Coolar has produced an electricity-independent medical refrigerator. The Coolar system uses warm water that is heated through solar energy and stored in a water tank. It does not use any moving parts, hazardous cooling fluids or lubricants. Thus, the Coolar system is a cheap, durable and sustainable solution for storage of vaccines, medicines and food in regions with unreliable or expensive electricity. The Coolar system runs independently from electricity by using solar heat, which makes it almost carbon neutral. Such a refrigerator can enable doctors and health professionals to preserve lifesaving medicine and vaccines in a reliable and eco-friendly way.

≈1Mt CO2e/year